By Janet Nolte

Solon Economist

SOLON- When Charles Searles heard in 1978 that Elmer Ponsar had decided to put his Solon mill and feed business up for sale, he called his daughter Shelley and her husband of two years, Frank Kuennen.

Shelley and Frank were at a crossroads. Shelley, a remedial reading teacher, learned she was out of a job due to cutbacks in the Title I program. Frank was considering either going back to college or, true to his upbringing on a dairy farm in Fayette county, returning to some kind of work in agriculture.

A marketing branch manager for Hubbard and Sunshine Feeds in Cedar Rapids, Searles encouraged Shelley and Frank to pay a visit to Ponsar at his mill. They did.

“Frank basically said, let’s give him an offer, and if he takes that offer, then it’s meant to be,” Shelley recalled. After a life-changing phone call with Ponsar, Frank told Shelley, “Well, we are now the proud owners of a feed mill in Solon, Iowa.”

“They kind of put everything on the line, and bought what was actually just a little feed store at the time,” said Greg Kuennen, 33, Shelley and Frank’s son. “They didn’t have any manufacturing capabilities then. As Dad talked to customers and saw a demand, he started to buy more mixers.”

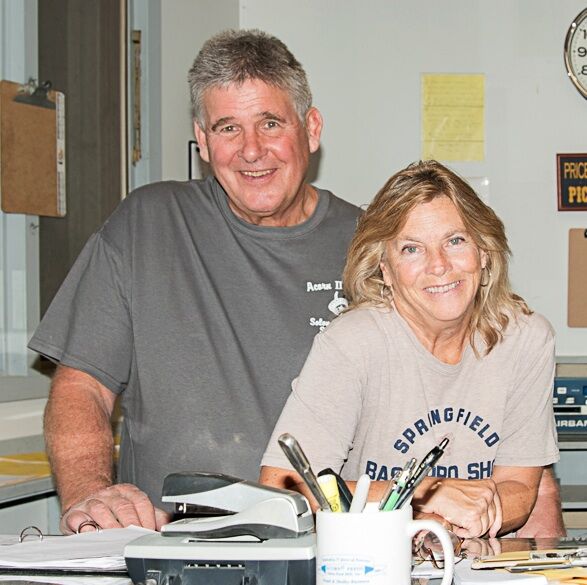

The Kuennens have owned and operated the Solon Feed Mill for 38 years. Business has grown substantially since those early years when two young Iowa school teachers took a gamble on a modest feed store. A store which has evolved and thrived in its original location at 310 S. Dubuque St.

Numerous upgrades to the building through the ’80s included remodeling and re-steeling, the installation of a 30-foot truck scale and roller mill and the addition of large bins and tall grain legs atop which the American flag has flown continuously.

In 1983, the Solon Feed Mill launched Acorn II Feeds, a private label line of products that continue to be milled, mixed, and bagged on site for both wholesale and retail customers. Derived from non-genetically modified organisms (GMO), their feeds provide nutrition for every kind of farm animal imaginable: beef and dairy cattle, swine, poultry, sheep and horses. About 10 years ago, a retail store was built to serve urban customers seeking healthy food options for the smaller animals in their lives. Along with food for cats, dogs and other “family livestock” such as goats and rabbits, the retail store also sells wildlife feeds for birds and deer.

The Solon Feed Mill is a family business. Currently, both Greg and his sister Kylie Mauser, 36, are actively involved. Greg works full-time helping manage the mill while Kylie, a busy mom who is raising three young children, pitches in at the Solon retail store.

“Kylie comes in once a week, and most people want to come in on the days she’s there,” Shelley noted. “But it is a little bit noisy at times because there are three kids here often!”

A teacher by training, like her mother, Kylie homeschools her kids. Greg’s wife, Nicole, works at the Solon Learning Academy, where their three children accompany her to work.

The route that led Greg and Kylie into the mill business was somewhat circuitous.

“After graduating from high school, I never thought I’d actually be in the feed mill business,” Greg confessed.

Prior to coming to work at the mill, the siblings started their own business in Solon, Savvy Coffee and Wine Bar. Much like their parents’ early decision, Greg and Kylie started down one entrepreneurial path and decided to change course after a couple of successful years.

“We learned a ton with Savvy,” Greg said.

“I liked it, but it wasn’t what I wanted to do,” he added. “And my sister wanted to teach. We both wanted to do something different.”

Since going to work full-time at the mill in 2005, Greg hasn’t looked back. He became a key partner in the business, working closely with his parents to expand operations and move toward organic certification of the Solon Feed Mill’s house brand of non-GMO products.

Greg loves the work he does, particularly setting and achieving goals to make operations as productive as possible.

“How can we do this better? How can we do this more efficiently? I find those challenges really fun,” he said.

Today, the mill has the capability to prepare and mix feeds based on customer specifications.

“Dad saw a need for someone wanting a feed with a different protein level or a different ingredient in their mix, and that’s where we started to do a lot more of the custom feed milling for our customers,” Greg explained.

Along with customization, Greg attributes the steady rise in demand for organic and non-GMO feeds as important factors in their business model.

“We’ve seen this non-GMO market grow and there’s demand for it, and one thing we can do is small custom batches,” Greg expounded. “Most mills won’t do that. We love being able to help out the small farmer. That’s really important for us.”

“Non-GMO is going like wildfire. It has really taken off,” Shelley added.

The focus on demand for non-GMO and organic feeds led to expanded operations with the acquisition and renovation of a feed store in Fairfax. Purchased in 2013, the Fairfax location needed lots of work, but the Keunnens saw great potential.

“The bulk capacity over there is a lot more than here,” Greg said. “The storage and grain capacity- that’s what we really needed. So we saw an opportunity.”

Initially, the facility was purchased for commodity storage, he said. “But then we thought why don’t we make a store out of it, too??So that’s when we started tearing down old buildings.”

In March, a grand opening for the newly remodeled storefront and bagging operation was held at the Fairfax location.

“We were doing so much custom bagging here (in Solon) that we couldn’t hardly keep up manufacturing feed,” said Greg.

Buying the Fairfax mill allowed the company to augment custom bagging services at a crucial time and offer greater convenience to customers farming in that area.

The high-output bagging line in Fairfax will also pave the way for the clean, efficient production and delivery of non-GMO and certified organic feeds.

“That’s going to be all-natural over there, no drugs,” Greg said.

“Some of the drugs we put in feed for cattle can kill a horse like that,” Greg said, snapping his fingers. “So you have to be really careful if you produce a feed for cattle with ingredients containing certain drugs, then go to mix feed for horses.”

Greg believes customers will value the peace of mind and confidence in the purity of made-to-order mixes that will be produced at the Fairfax facility.

The Solon Feed Mill’s growth and ongoing success are the result of hard work and perseverance through tough times. Remembering one of the worst days in the mill business, Shelley described what happened May 7, 1981, when a trench was being dug for a new weigh scale.

“I had (the kids) on my bicycle, one on the front, one on the back, when we came up and saw the whole wall was caved in. I turned the corner where the old post office used to be? and the whole north side of the feed mill was gone. I just stopped and cried.”

Fortunately, no one was injured in the accident and Frank forged ahead, maintaining business as usual while adding a new foundation and wall to the construction plans already underway for the new scale.

Having to face adversity themselves has, no doubt, fueled the Kuennens’ commitment to community and neighbors beset by hard times.

“Whenever there’s anything that hits the community in a bad way, we want to be able to help,” said Greg. “My parents have shown that throughout the years we always try to jump in where we can. Community involvement has always been a huge priority with us.”

For the Kuennens, local competitors are part of that community.

“When the flood 2008 happened, Diamond V mills in Cedar Rapids was down, and so we stepped in and bagged a lot of their product,” Greg said.

Even closer to home, the Solon Feed Mill has always been there to lend a hand to their competitor just down the street.

“F.J. Krob and us, we get along really well together. Even though we sell sometimes to the same customers, if they have a truck go down, we let them use one of ours and vice versa,” Greg said. “It’s really nice having those friendly, competitive business relationships.”

In addition to making the Fairfax mill an all-natural and non-GMO facility, Greg’s plans include extending the kind of made-to-order feed mixing routinely done for farmers to customers who shop the retail store for pet and wildlife food.

“One thing we’re going to do this year is have bulk birdseed bins so that people can mix their own,” Greg said. “A lot of people don’t want millet, or a lot of people don’t want corn. So this way we can do just safflower and peanuts, or whatever you want.”

Customers also get advice and a better understanding of why certain ingredients are best for particular kinds of birds.

“I’d really like to try to sell the experience here. Let people know why these birds want this seed,” Greg said. “They will be able to look at it and feel it.”

4 decades of family feed

September 21, 2016

4 decades of family feed